In today’s fast-paced business environment, efficient storage solutions play a pivotal role in enhancing productivity, safety, and operational flow. From small workshops to large-scale warehouses, the ability to manage stock effectively can make the difference between success and stagnation. Companies across sectors are continuously exploring new ways to optimise their storage capacity while maintaining accessibility and safety standards.

One of the biggest challenges for businesses is dealing with bulky or irregularly shaped items. Traditional racking systems, while effective for uniform stock, can become limiting when items vary significantly in size and weight. This is where innovation in storage design has transformed how industries manage their spaces, allowing greater flexibility and adaptability.

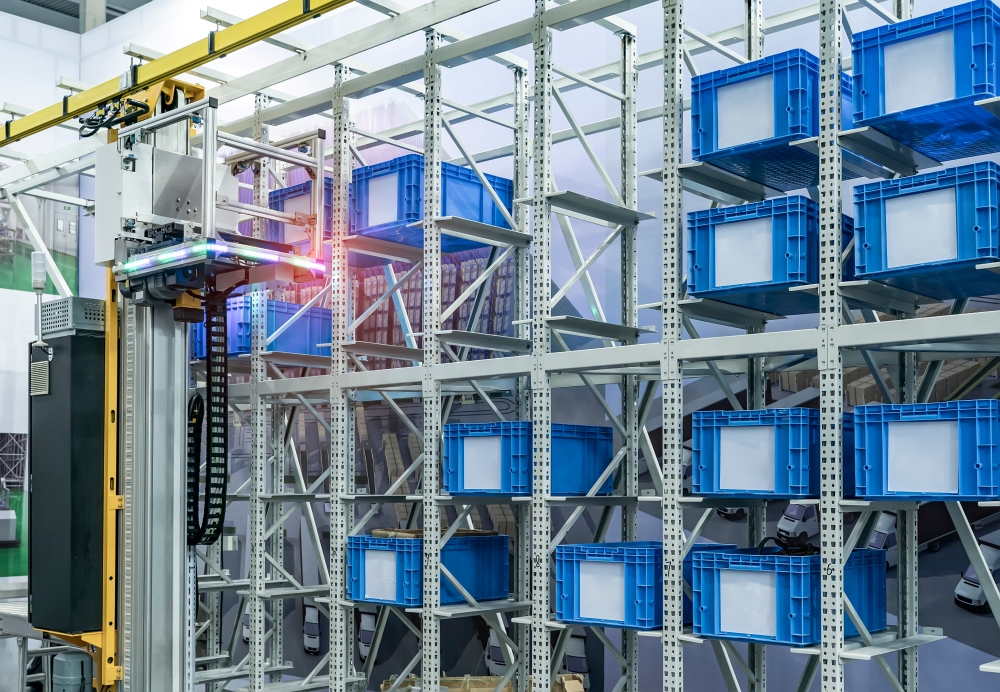

Modern warehouses now demand more than just basic shelving. They require integrated solutions that balance space-saving techniques with durability and ease of access. Innovations in materials have enabled stronger yet lighter storage systems, capable of holding heavy loads without compromising stability. Furthermore, the rise of automation in warehouses has added another layer of complexity, as shelving needs to accommodate robotic picking systems and other smart technologies.

For example, manufacturers storing large building materials or metal components often need a system that allows quick access without the constraints of enclosed storage units. A well-designed framework not only increases safety but also helps workers locate and retrieve items faster, saving valuable time on the floor. In such cases, a solution like cantilever shelving provides the ideal balance of accessibility and strength, supporting awkward or oversized products in a way that standard pallet racks cannot.

Beyond functionality, safety is another key driver in the choice of storage systems. Poorly organised or inadequate racking can increase the risk of accidents, which not only harm staff but can also lead to costly downtime. Regular inspections, adherence to load limits, and staff training are essential practices for maintaining a safe warehouse environment. The right shelving contributes to these efforts by ensuring stability and reducing hazards associated with improper stacking.

Sustainability has also entered the conversation around storage design. Businesses are increasingly under pressure to adopt eco-friendly practices, and storage is no exception. Recyclable steel structures, modular designs that extend product life, and energy-efficient automated systems are becoming standard features. With these developments, companies can align storage infrastructure with wider environmental goals while still enjoying efficiency gains.

The flexibility of modular systems further enhances warehouse adaptability. Adjustable frameworks allow businesses to adapt quickly as their inventory changes. In industries where demand fluctuates seasonally or where product lines evolve rapidly, this adaptability ensures that companies remain agile without the need for costly overhauls.

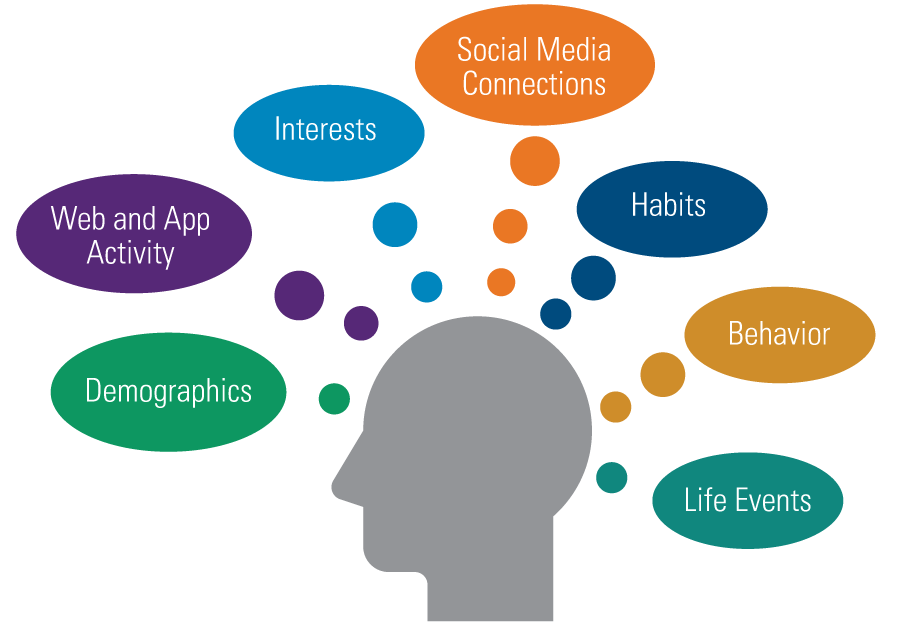

In addition, the digital transformation of storage systems is opening new doors. Advanced tracking technologies, such as RFID and IoT sensors, integrate seamlessly with shelving systems to monitor stock in real time. This improves inventory accuracy, reduces shrinkage, and allows managers to make more informed decisions. For businesses working in sectors where margins are tight, even small efficiency gains can deliver significant returns.

Ultimately, the right storage solution is not just about saving space—it’s about unlocking operational potential. Businesses that invest in tailored shelving systems gain long-term advantages, including improved workflows, safer environments, and reduced costs. As industries continue to evolve, so too will the demand for smarter, more resilient storage solutions. By staying ahead of these trends, businesses can ensure they remain competitive while meeting the practical needs of their workforce.