In modern manufacturing and industrial environments, efficient heating systems play a crucial role in maintaining productivity, reducing waste, and optimising energy use. From drying materials and curing coatings to maintaining consistent temperatures for process reliability, heating technology has evolved significantly over the past decade. As industries move toward sustainable and automated operations, the demand for precise, high-performance heating systems has grown exponentially.

The Shift Toward Smarter Heating

Industrial heating is no longer just about generating warmth—it’s about control, consistency, and cost savings. The integration of smart technologies, such as IoT sensors and programmable controllers, allows for precise temperature management across diverse applications. Facilities can now monitor energy consumption in real-time, adjust performance based on workload, and even predict maintenance requirements before system failures occur. This shift toward data-driven control has become a key differentiator in industrial operations striving for efficiency and sustainability.

Energy Efficiency and Cost Control

Energy remains one of the largest operational costs for manufacturing businesses. By upgrading to energy-efficient heating systems, companies can significantly reduce overheads and carbon footprints simultaneously. Insulated heating units, automatic shutdown features, and advanced heat recovery systems are just a few innovations that have helped industries cut down energy waste. Governments and environmental bodies are also providing incentives for adopting eco-friendly solutions, making the transition to efficient heating both financially and environmentally beneficial.

Meeting the Demands of Heavy-Duty Applications

Large-scale industrial processes often demand robust, high-capacity heating equipment capable of handling extreme conditions. This is where technologies like 3 phase heaters prove invaluable. Designed to deliver balanced power distribution, they provide greater reliability and performance for demanding environments such as metal fabrication, chemical processing, and power generation. Their ability to operate efficiently under continuous use makes them a staple in industries where downtime can result in significant financial losses.

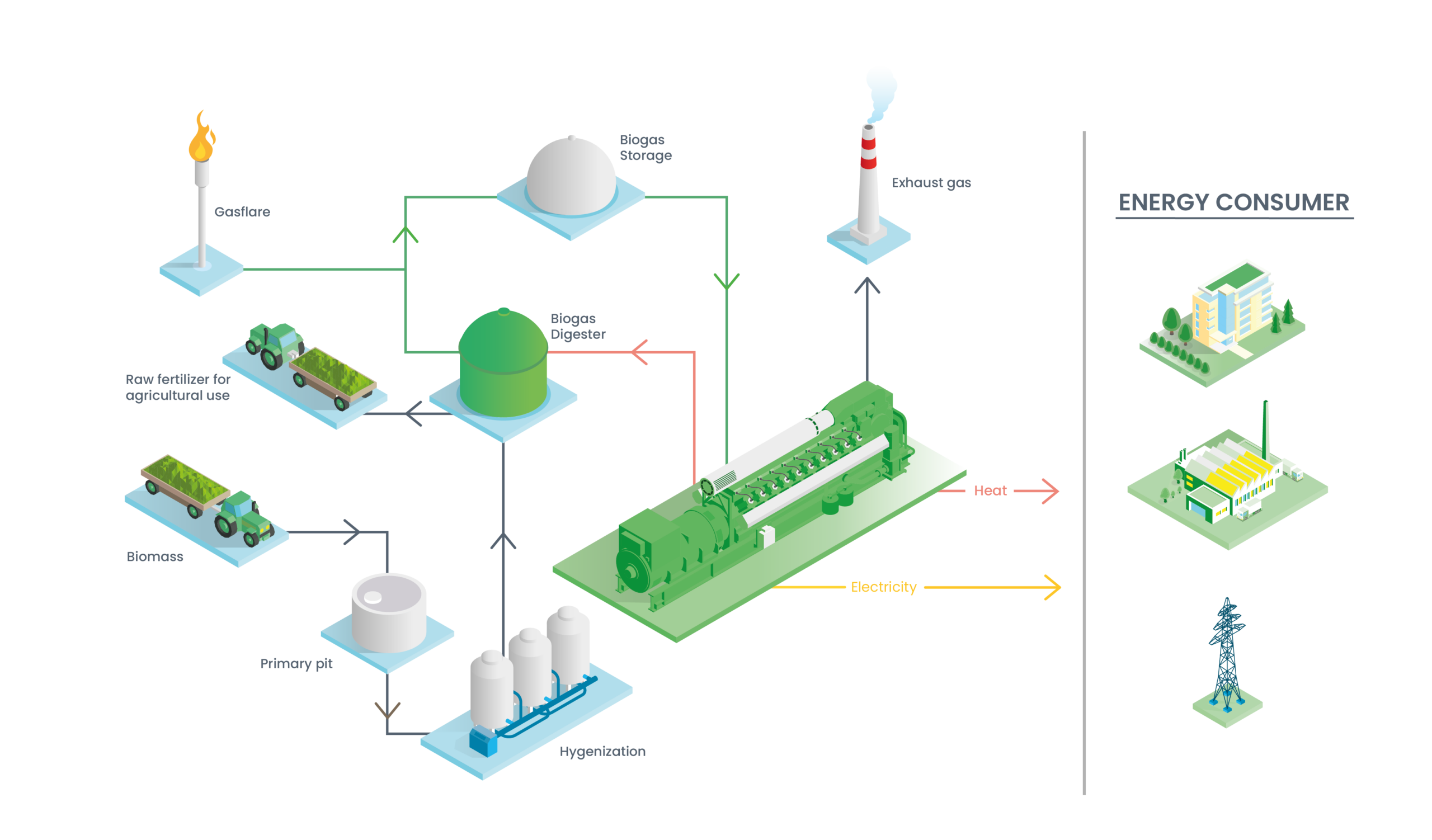

Sustainability in Industrial Heating

With the global shift toward carbon neutrality, manufacturers are exploring alternative energy sources and sustainable heating technologies. The use of renewable energy, such as solar or geothermal power, is increasingly being incorporated into heating systems. Additionally, advancements in heat pump technology and low-emission burners are helping businesses meet environmental regulations while maintaining operational excellence. Forward-thinking companies are also adopting circular economy principles—recovering and reusing heat from production processes to reduce waste.

The Role of Automation and AI

Automation and artificial intelligence are reshaping the future of industrial heating. AI-powered systems can analyse energy patterns, automatically adjust settings for optimal performance, and predict potential faults before they cause downtime. Predictive maintenance not only reduces costs but also extends the lifespan of heating equipment. This kind of technology-driven reliability is especially important in industries with critical process requirements such as pharmaceuticals, food processing, and electronics manufacturing.

Future Outlook: Innovation and Adaptation

The industrial heating sector is poised for continuous innovation. Future developments will likely focus on hybrid energy models that integrate traditional power with renewable sources. Digital twins—virtual models that simulate the performance of heating systems—will further enable operators to optimise processes and test efficiency improvements before implementation. These advancements are set to make heating systems more sustainable, flexible, and cost-effective, ensuring they remain integral to the evolving industrial landscape.

In conclusion, industrial heating has evolved from a basic utility into a strategic component of operational efficiency. Whether through intelligent control systems, sustainable power sources, or advanced hardware design, businesses that invest in modern heating solutions are better equipped to compete in an increasingly demanding marketplace. As industries continue to innovate, heating technology will remain a cornerstone of productivity and progress.